A simple machine is a mechanical device that changes the direction or magnitude of a force. In general, they can be defined as the simplest mechanisms that use mechanical advantage (also called leverage) to multiply force. Usually the term refers to the six classical simple machines that were defined by Renaissance scientists:

LEVER

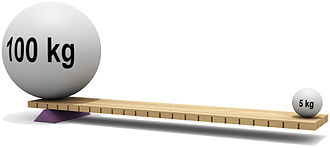

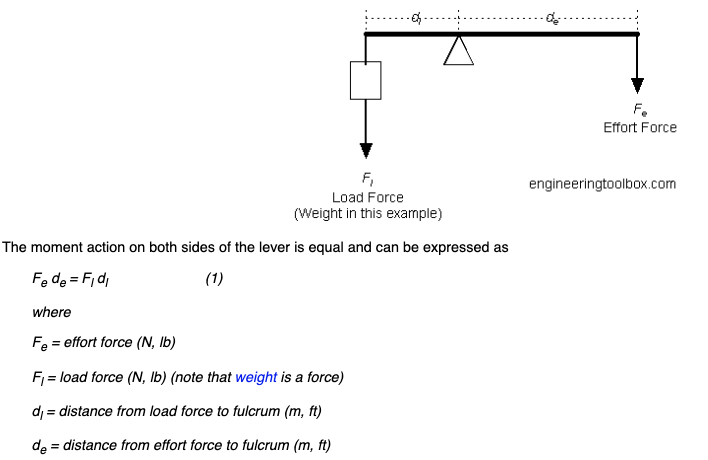

A lever is a simple machine consisting of a beam or rigid rod pivoted at a fixed hinge, or fulcrum. A lever is a rigid body capable of rotating on a point on itself. On the basis of the location of fulcrum, load and effort, the lever is divided into three types. It is one of the six simple machines identified by Renaissance scientists. A lever amplifies an input force to provide a greater output force, which is said to provide leverage. The ratio of the output force to the input force is the mechanical advantage of the lever.

fulcrum or pivot, load and effort

Classes of levers:

Levers are classified by the relative positions of the fulcrum, effort and resistance (or load). It is common to call the input force the effort and the output force the load or the resistance. This allows the identification of three classes of levers by the relative locations of the fulcrum, the resistance and the effort:[4]

- Class 1: Fulcrum in the middle: the effort is applied on one side of the fulcrum and the resistance (or load) on the other side, for example, a seesaw, a crowbar or a pair of scissors. Mechanical advantage may be greater than, less than, or equal to 1.

- Class 2: Resistance (or load) in the middle: the effort is applied on one side of the resistance and the fulcrum is located on the other side, e.g. in a wheelbarrow, a nutcracker, a bottle opener or the brake pedal of a car, the load arm is smaller than the effort arm, and the mechanical advantage is always greater than one. It is also called force multiplier lever. However in an oar the load arm is greater than the effort arm, and the mechanical advantage is less than one.

- Class 3: Effort in the middle: the resistance (or load) is on one side of the effort and the fulcrum is located on the other side, for example, a pair of tweezers, a hammer, or the jaw. The effort arm is smaller than the load arm. Mechanical advantage is always less than 1. It is also called speed multiplier lever.

Law of the lever:

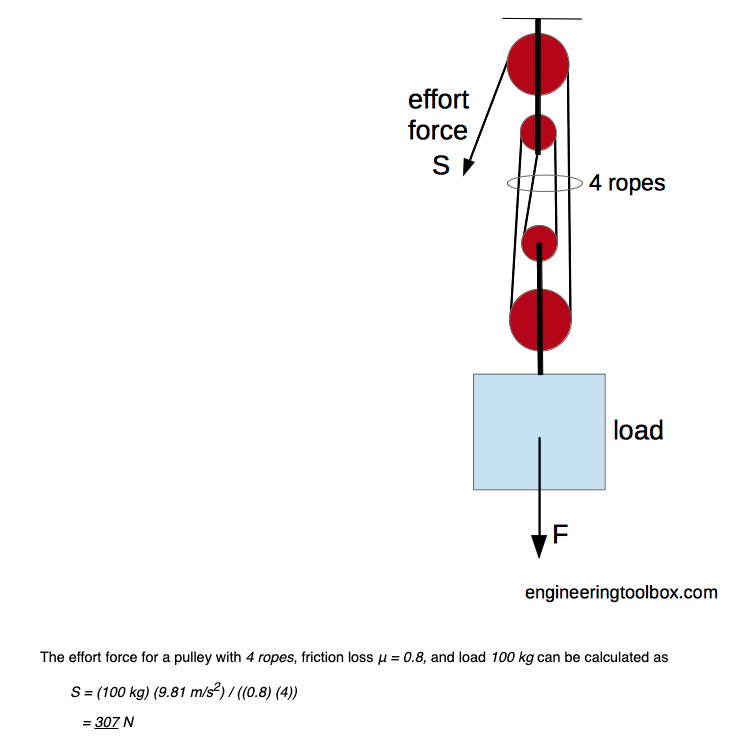

PULLEY

A pulley is a wheel on an axle or shaft that is designed to support movement and change of direction of a taut cable or belt, or transfer of power between the shaft and cable or belt.

A rope and pulley system—that is, a block and tackle—is characterised by the use of a single continuous rope to transmit a tension force around one or more pulleys to lift or move a load—the rope may be a light line or a strong cable. This system is included in the list of simple machines identified by Renaissance scientists.[9][10]

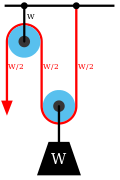

If the rope and pulley system does not dissipate or store energy, then its mechanical advantage is the number of parts of the rope that act on the load. This can be shown as follows.

These are different types of pulley systems:

- Fixed: A fixed pulley has an axle mounted in bearings attached to a supporting structure. A fixed pulley changes the direction of the force on a rope or belt that moves along its circumference. Mechanical advantage is gained by combining a fixed pulley with a movable pulley or another fixed pulley of a different diameter.

- Movable: A movable pulley has an axle in a movable block. A single movable pulley is supported by two parts of the same rope and has a mechanical advantage of two.

- Compound: A combination of fixed and movable pulleys forms a block and tackle. A block and tackle can have several pulleys mounted on the fixed and moving axles, further increasing the mechanical advantage.

to be continued…